As moored ships

• How are moored ships

Or why it is necessary to erect monuments to engineers, designers and inventors.

The tanker "Governor Farkhutdinov" at the pier. Port of Fos, France.

Kratenko Background. Kratenko, because on this subject can navayal ten positions, and then, the topic will not be fully revealed. And then the background to bring up to date.

Mooring system, one of the oldest devices on board. This device came with the ship, and go away with the ship. It is understood that for centuries the device has changed, but only in technical terms, the very purpose remains the same - to keep the boat at the pier. Well, not necessarily at the pier, but hold.

When the mooring lines were made from plant materials, and I can hardly imagine the nightmare - struggle with these tips. Then they invented nylon, but has not become easier. Nylon ends of the same, the more zvizdets. Capron wet, absorbs water and sinks in water.

A little cold, and wet nylon end hardly bent. At the same time, it is strongly stretched, it also does not make it safe. When excessive stretching it bursts, and flies back on line tension, with terrible force. Get under a bursting of the end - just will not get off the injury, it is almost guaranteed a disability, and even death. Personally I am seen killed this end, the sight of something else. And it seems that it was after the appearance of nylon navy appeared TB is usually - not stand in the tension of the line ends. And, for all the shortcomings of nylon, it is still common in the Navy. To replace Capron came another synthetics - propylene. Propylene is a lot easier to nylon, it does not absorb water, does not sink and float. Not much stretched. Propylene is much easier mooring, even in extreme cold it retains flexibility. And now most of all, it is the mooring of propylene.

There are exotic - Kevlar. This is generally a miracle, not ends - thin, logonkie not subject to strong tension. But there are drawbacks - are afraid of contact with them oil. A fairlead under the Kevlar must be carefully polished. Therefore, a large spread of Kevlar not received.

On ships large tonnage used steel ends. At the working end of the steel end attached shvartnogo so-called "tail" (tail). The tail is made of synthetics, and one of the intended "tail" - the gap at an excessive load on the end of the mooring.

Photo on the cover is clearly visible and "tails" and he stalnyak.

Here, "Governor Farkhutdinov" (Farik)) from the stern. The same Fos, France.

Also seen stalnyak and "tails."

But the tanker in the same Fose synthetic ends. Photo mine, if that, yes.

Mooring lines on the ship have their names. And the classical scheme moored vessel looks like this:

There are nuances, for example, the number of the day, but the classic looks that way. How does the mooring?

To a suitable vessel tows, attached to it (typically on the superstructure cut from the stern, and on the tank).

Tug help vessel approach to the jetty, and to work on the focus to the pier. After a tug boat put into the desired position, with the board on the beach serving ends. Beach receiving end, it leads to the coastal guns, then start to fill (to pull), these ends.

If the ship is equipped with mooring winches, then there's just - stuffed to the desired tension, the winch put on the brakes, and that's that.

If no winch starts dancing ... apple and jig. End tensioned via warping drum winch or capstan.

Then take the end of the stopper, and transfer it from the spire on bollard - eight.

So, kratenko.

Tumbling on the mooring can last an hour or two, and three. Differently. Factors are sufficient.

And here comes a device that is to fundamentally change the business.

Ship ends are not used at all.

Sucker works.

Automoor.

The company Trelleborg, so to speak, is.

Mooring will now take less than a minute. Tugs just enough to expose the ship to the desired position at the pier.

Unmooring also will take even less time.

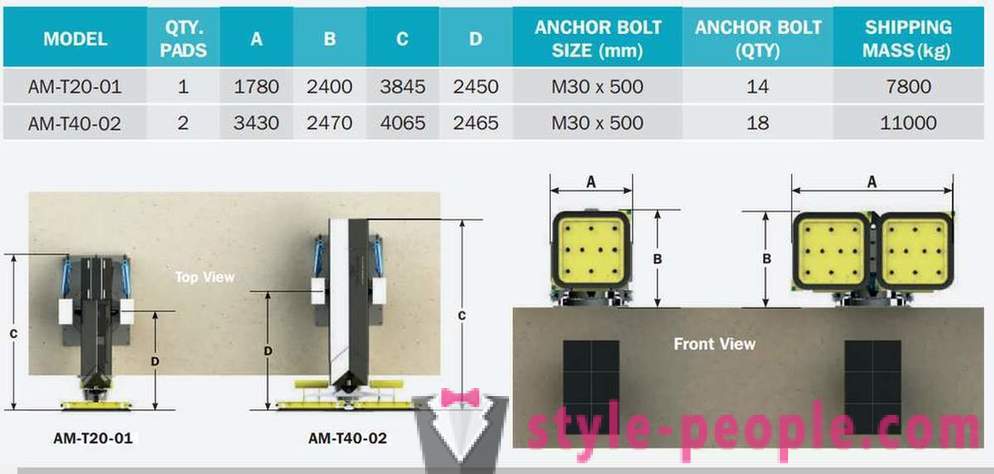

The suction cup is available in two forms - one with a working area, and two. It depends on the piers that serve tonnage.

The working area of a single sucker - 5 4 square meters, double - 7 5 square meters.

The mooring complex.

Suckers and Defender.

But during the ship's stay at the pier is unloaded or downloading happen tides. Therefore, the watch watching Mooring lines, periodic rounds of the ship, and if you want to potravlivayut, or vice versa, pull the ends.

Management of the suction cup is computerized. There are already computer monitors changes in precipitation and other related phenomena.

In general, the appearance of this sucker, it SmartPort concept from the company Trelleborg.

What to say? Excellent a stray. Now it is not necessary to freeze and get wet, overstrain, dragging ends. Only then to throw the ladder, and you're done. And, since the coast is served in some ports and ladder.