The manufacturing process of the world's largest passenger aircraft

• The manufacturing process of the world's largest passenger plane

The giant double-decker airliner Airbus A380 - the largest passenger aircraft in the history of world aviation, its maximum capacity of 853 passengers in odnoklassovoy layout. The first copy delivered to the customer in 2007, more than 110 cars built today! Today I want to show the A380 assembly line at a factory in Toulouse, the scope and size of what you see is impressive.

Many believe the aircraft is aesthetically unappealing. I strongly disagree with this statement, what is more, I consider it particularly beautiful and elegant heavy. Slowly soaring A380 beautiful!

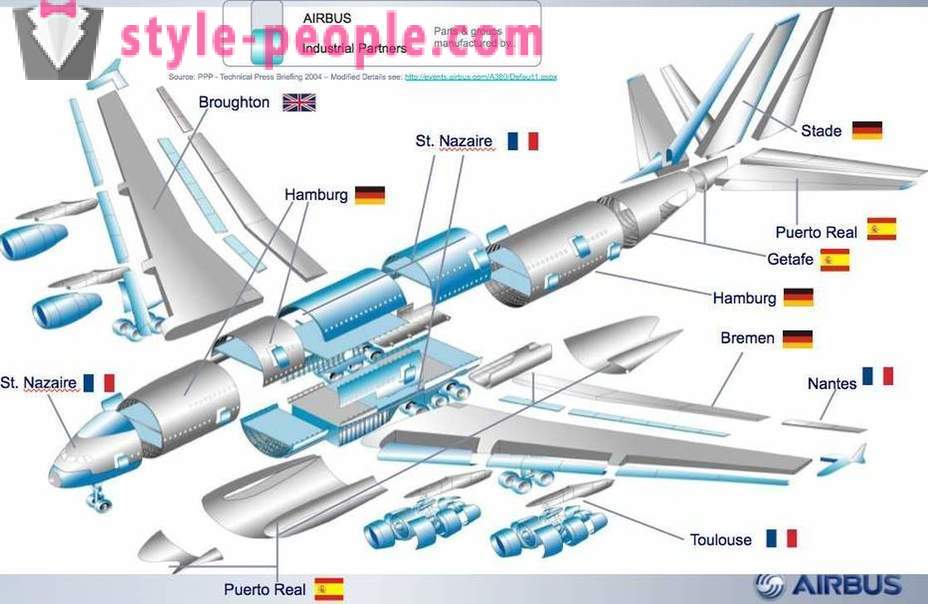

A380 Each plane consists of about 4 million. The individual components, and 2, 5 million. Parts produced 1500 companies in 30 countries around the world.

And now go to the factory. This production capacity layout of the factory in the town Balanyak near Toulouse, orange - this assembly shops A380:

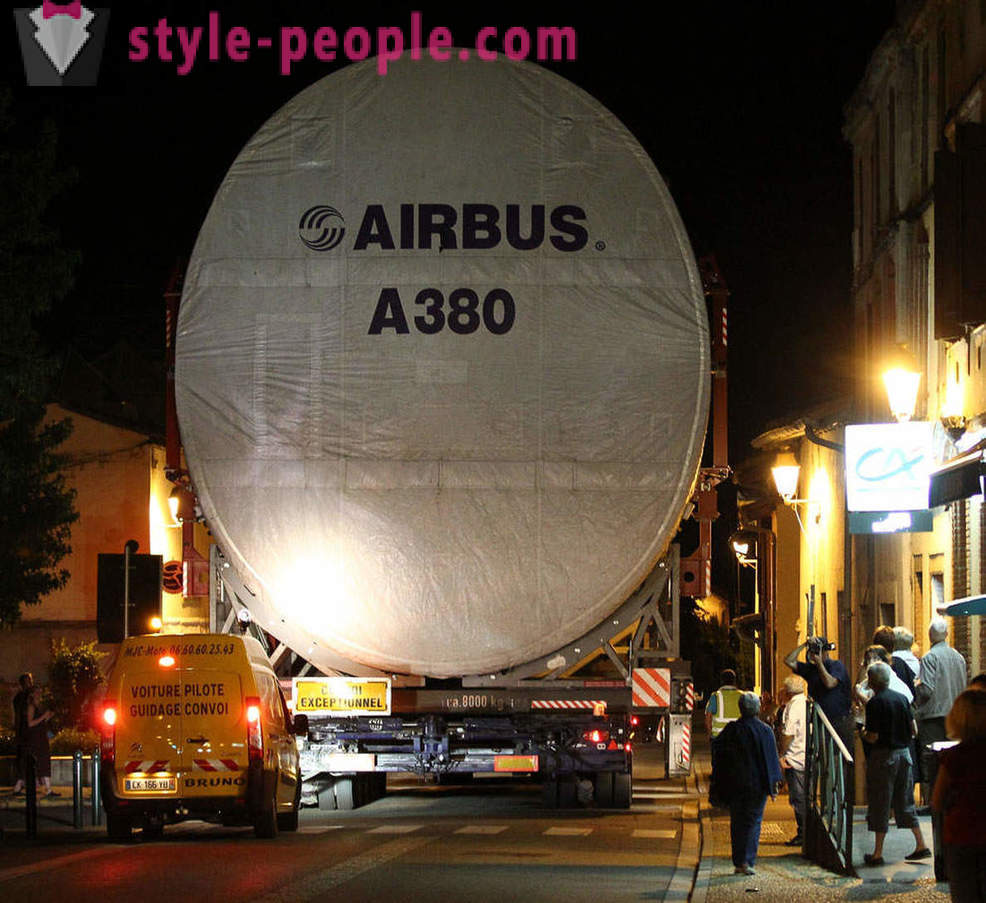

The main elements of the fuselage of the A380 can not be transported by air, so they were being taken across the sea and the river at a specially adapted for this purpose barges, and then twice a month on the cars - this is called "the night the convoy."

Specifically for this aircraft Airbus has developed a unique logistics system, which is involved in sea, river, air and road transport. From the town of Lisle-Jourdain, about 30 km from Blagnac, exactly at 22:00 the night the convoy starts moving at a speed of 15-20 km / h, so as not to interfere with the movement - six trailers, on which are placed all the parts of the aircraft are sent to two hours the way to the final point - the final assembly line in Blagnac. Section of the fuselage with a diameter of 7 meters directly driven through the narrow streets of the town. But this is the only possible and the most optimal point of delivery of the liner elements to the plant:

And then begins the assembly of the aircraft with serial movement between t. N. "Stations". Length, width and height of the assembly shop is 490, 250 and 46 m, respectively.

In the first assembling station occurs and the connection between the fuselage sections are:

Next, the assembling of the wings and vertical stabilizer:

Area A380 wing - 845 sq. m, which is 54% more than the Boeing 747-400!

And it's not just the tail ... it's FIVE giraffes in height!

Preparing the engine pylons:

The aircraft is assembled, the next position is made installation of the passenger compartment and the cockpit:

Each of the main landing gear capable of withstanding loads up to 260 tons, which is equivalent to the weight of 200 cars Golf class:

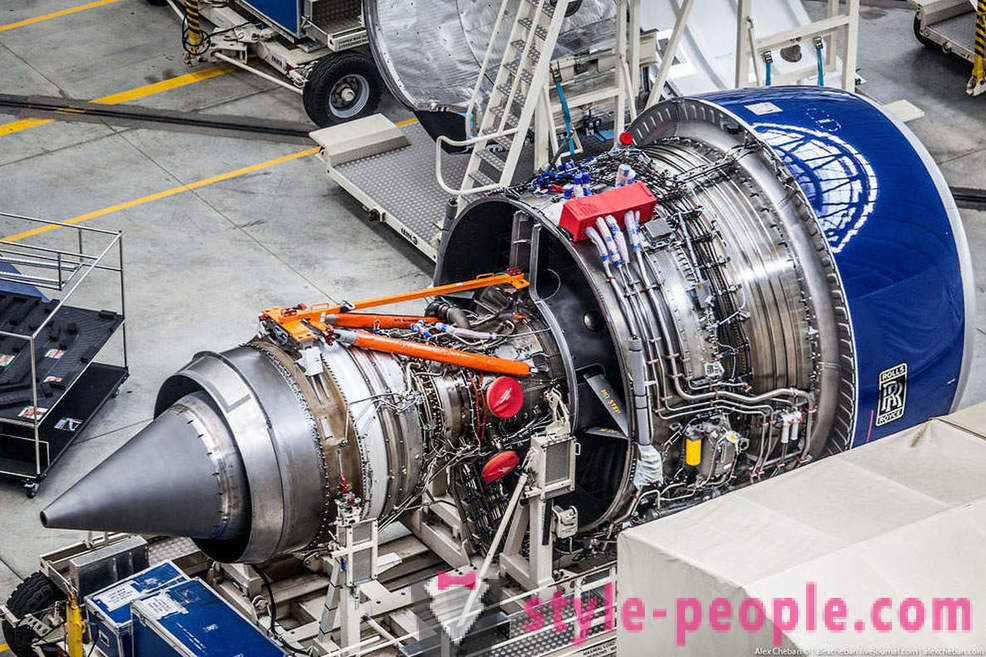

And finally, the last assembly station, home of the installation of engines and passenger seats:

the A380 can be equipped with two types of engines: Rolls-Royce Trent 900 or Engine Alliance GP7000. Only two of the four engines are provided with thrust reversers. Noise reduction is an important requirement in the design of A380, which is partially reflected in the design of engines. Both types of motors enable the aircraft meet noise limits for QC / 2 at departure and QC / 0.5 at arrival established London Heathrow Airport.

A380 - the most fuel efficient aircraft in its category. This single haul liner, which consumes less than 3 liters per passenger carriage 100 km (typical arrangement 525 seats).

The total area of the A380 cabin - 554 square meters. M. Two full decks: main deck - the widest in the world passenger compartment (6, 5 m); upper deck - full wide-body aircraft cabin (5, 8 m). Aircraft air-conditioning system is equipped with the most advanced filters that provide uniform air flow to all parts of the ship. The air in the cabin (capacity 1570 cu. M) is completely replaced every three minutes! A380 has the quietest passenger cabin in the history of world aviation, I am convinced personally on the way from Frankfurt to Singapore.

The aircraft is assembled! Next comes a series of test flights and painting at the plant in Hamburg, where the A380 is transferred to customers.

At present, produced more than 110 A380 aircraft, produced monthly and sent to customers an average of 2, 5 aircraft. At the moment, the A380 has been in operation at 20 airlines. The largest fleet of A380 - the Emirates.