Feeder feeder own hands: a step by step description. Feeders Feeder own hands (drawings)

With winter approaching, few people will be able to actively attend fishing, while many do are unlikely to be such a desire. The presence of characteristic weather and cranky enough bite - all this is not the best conditions for avid angler.

prepared in advance

However, after the first spring warming, as well as a full descent of the ice everyone will expect the long-awaited departure of the nature, and if you are also hiding in anticipation of this time, it is best to familiarize yourself with some useful tips, which allow to prepare ideal gear. In particular, as the fishermen say, "Sani prepare summer and feeder - in the winter" - so even in cold weather you need to consider all sorts of little things, as well as purchase the necessary gear in order to eventually have been immediately feeder feeder. With their hands to make them know how far away a few, though these skills are important enough.

Today it is a very good option for those who want to save their own funds, and at the same time get a really reliable device, as the production of which does not have to constantly doubt.

How to make a bird feeder to feeder?

In this article we will look at the quickest and easiest way of how to make a feeding trough for the feeder with their hands. In other words, in this case it is not necessary to use soldering and other professional equipment, but at the same time you will spend a minimum of time and effort to produce such high-grade products.

Is there a difficulty?

It is worth noting the fact that the most difficult for most people here is the casting of lead, but the feeder feeder is made with their own hands the only way. Fortunately, modern stores, you can easily find specialized forms for different casting weights.

How much do they need?

If you understand how to make a feeder for feeder with your hands, you will be enough only a few such products for a full fishing season. Do not forget that even if you decide to buy a pig in a already prepared by lead, its own feeder will cost several times cheaper. Cost grid is extremely low, and only one square meter would be sufficient to produce about a dozen different feeders.

Among other things, we can not say that the working procedure itself brings a lot of fun, so how to make a bird feeder to feed their own hands can not all. Especially the process fueled by constant thoughts about the future trophies.

What do I need to have?

Initially, for the manufacture of feeders model you need to bring the following:

- metal mesh. Ideally, you should use a 5x5 grid with cells.

- wire. It fits almost any wire, but it is best to use the most reliable.

- Wooden dice. In this case, the shape does not matter, since the plates are intended for uniform bending grid.

- Good pliers or tongs. This tool will be used to secure the lead clamp.

- Cutters.

In this way, we can say that the set of tools is minimal, so, in principle, every angler will be able to deal with how to make a bird feeder to feed their own hands.

How do I do?

For the manufacture of this product you will need to follow the simple instructions:

- Using the wire cutters, cut out of a grid cell, the size of which must be 8h21. It is worth noting that the size is optimal for the production of high-grade feeder rectangular shape.

- With the help of a special wooden slats mesh bends up to three cells, then five, and twice more at five to ultimately there are only three cells.

- The two extremes of the three cell surfaces must be combined in such a way as to each other, they went clear on one square.

- This design is fixed by means of a wire. It is worth mentioning the fact that in certain situations you can do even without a lock, because in practice bent lead quite well hold any catch, but in any case it is better to use the wire if you need a quiet fishing. Feeder-feeder with his own hands for the flow is made simple enough, but do not forget that the main feature of this device is reliable, so it is best to provide it to the maximum.

- After you have prepared the form, you can start casting lead.

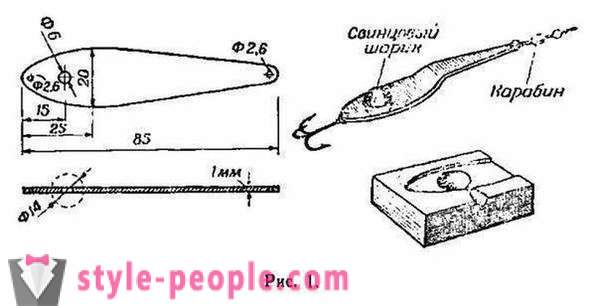

- At once it is worth noting the fact that the lead cast is a fairly simple procedure, but do not forget that it is laborious and dangerous process. It is mandatory all work must be carried out in specialized gloves, and the room must necessarily be ventilated during melting. Before use in the manufacture of feeders feeder own hands drawings, should be cleaned and dried form, in which you will be working with the most appropriate to use a flat shape, by means of which will normally lead to curl around mesh manufactured feeders. This technology involves the use of additional fasteners, while the most economical is the use of standard gypsum. Plaster mold itself can be a good idea to replace the purchase, as well as it can help to make a perfect shape and adjusted as necessary. Thus, if necessary, it can be made even feeder-bullet for the feeder with their hands.

- represent Georgia shape for the trough and produce a similar version of the tree.

- Gypsum pre-kneaded, after which it is immersed prefabricated wooden dummy contact. You can use a variety of sizes for recess, and if there will be some incidents, the shape may change or be Fixed with a standard chisel. Of course, the standard form of the purchase is made from two halves, which allows you to make the most smooth and beautiful Georgia, but the use of a plaster version is much more affordable in terms of financial costs, and at the same time he completely satisfies the requirements of novice masters.

- In the end, if you look strong, you will notice not the straight edge of shipments, or may be a beard, but if necessary, it is ground, even if you made the first time for the feeder trough with their hands (pictured above). In the overwhelming majority of cases, experts recommend to place the load with a thickening close to the center, but at the same time make it thin enough on the sides in order to achieve the most efficient bending.

- Prepared lead mounted on the grid.

- Do not forget to also take care of the use of really high-quality tooling and fixtures. If you made zakormochnaya feeder feeder with their hands, the most optimal is to use a specialized feeder rubber, metal rings, a thick fishing line, rubber belt or wire. If necessary, you can immediately install karabinchik and swivel mounts are on the feeders or you have to use them later in the installation.

A further embodiment of

In this case, you will need to have three metal plates. In this case, you'll have a slightly different feeder.

№2 The

Method to feed their own hands here provides as follows:

- The presence of a thin metal plate which is used as a side wall of the mold and will bend, and equipped bottomed for lead. With bedplate can provide the most effective fixation structure.

- The next plate is more thick, but it is equipped with a hole to fill. this hole is done independently by the standard of a file if necessary.

- The third plate will be the middle part of our form, and at the same time on it necessarily need to cut out the space that is necessary for normal casting.

In this case the feeder feeders with their hands for the flow are produced by collecting all the plates in the unitary structure, followed by pouring mold.

What do I need to consider?

Before spending lead pouring, form should be as carefully wiped, and this is quite important. In the overwhelming majority of cases, experts recommend to use different forms of feeders initially so that later you can choose the best option, especially suitable for fishing.

So how far away is not always possible to make smooth curves of the mesh at right angles, can be used to help specialized vise or wooden rails.

Plastic feeder

Now let's see how to make a plastic feeder feeder with their hands out of the bottle. To do this, you need only three basic components - that's just the bottle itself, a clip and a lead weight.

The advantages and features of

Immediately it is worth noting the fact that the main advantage of this technology is the highest possible availability of all materials. At the very least, just enough to find the first two elements, while the lead get today is not as simple as it might seem at first glance. Some experts recommend the use of specialized, self-adhesive weights made of lead, if necessary, are used in modern tire changers companies for wheel balancing. Once you will have everything you need, you can begin to make a bird feeder to feeder.

How to do it?

Initially, you need to determine the order, how much weight will be manufactured your feeder, because it was from him bude directly depend on the length of the final product. Optimally will split a plate of lead weighing up to 60 grams in half. Thus, you get more of the same weights, which weighs thirty grams, while for the production of feeders in this case would be quite enough to use, and one such piece.

Once your shipment will be made for the feeding trough, it can already be engaged in the production of carcass. For this purpose it is necessary to use sharp-edged knife and a metal ruler with which originally held the line, and then cut off all unnecessary roughness. If necessary, also provides for the use of the pen.

Now, cut to the desired width of a strip of plastic. The lead plate is applied to the edges of the workpiece, while on the flat side of the plastic held knife. Now the line is applied to the painted dash, and then hold the line with a knife.

Once the lines will be cut all the excess, plastic is rolled into a tube. After determining the optimal amount of your feeders completely cut off all unnecessary parts. The most important of these is the correct account of the plastic overlap, which is formed in case of further binding stapler. It is worth noting that if you have made such a feeder (method feeder) with his hands, the overlap should not exceed 1.5 cm.

Plastic skeleton stapler is attached to each side. The diameter of the feeder in this case will be 4 cm, while the length of 4.5 cm. Now the cargo is adhered to the butt-joint frame, an adhesive tape unstuck on the sinker, whereupon he applied to plastic and firmly pressed. In the end, you will have to prepare a clip for fastening, in the manger to do a few holes and connecting the clip. The final element is a soldering iron to burn a hole with the hole should be tooled moistened fingers.